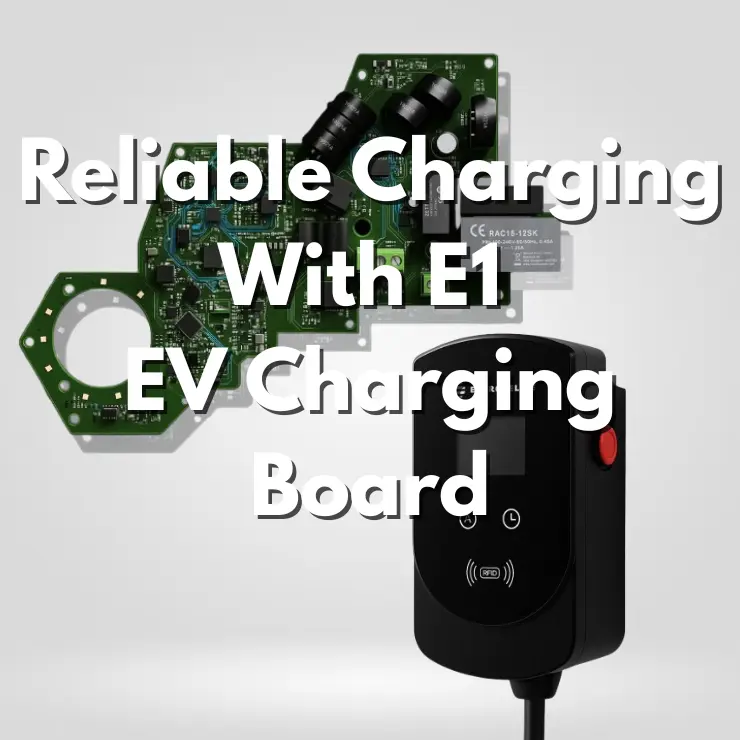

Reliable Charging With E1 EV Charging Board

While mechanical protection is considered important for an EV charger, the EV Charging Board—known as the PCB—is also regarded as a crucial component in ensuring smooth operation. In this article, 3 important features found on the PCB of the E1 will be highlighted, showing how they contribute to extending the lifespan of the EV charger.

Why does features on EV Charging Board (PCB) matter?

Reliability is established during the design phase of the EV Charger Board. The elements and layout that are integrated into the EV Charger Board are considered based on how effectively it will perform in real-world conditions, while stable performance is ensured.

Reduced maintenance and enhanced safety can be achieved when well-integrated features are utilized on the EV Charger Board.

Thicker Use Of Copper For EV Charging Board (PCB)

EV Charging itself generates copious amounts of heat due to the high current that’s used. Hence, thicker or heavier copper are utilized to give support. The enhancement ensures that the electrical pathway remains intact longer over time. Among the positives that the feature brings are:

- Better Heat Dissipation

- Less performance degradation during higher power demand such as 22kW charging

- Extend the lifespan of the E1 EV Charger through better thermal control

Built-in Surge Protection

Voltage fluctuations that may occur during thunderstorms or from the grid are known to potentially cause damage to the EV charger. However, the E1 EV Charger Board has been integrated with a surge-protection device (SPD), through which sudden electrical surges are detected and diverted away from sensitive components. This feature is especially beneficial for users who are frequently affected by::

- Areas that are prone to lightning strikes

- Frequent power outages

- Unstable grid connections

Protective coating of the EV Charging Board (PCB)

Conformal coating is applied onto the EV Charging Board as a proactive measure against agents of moisture and corrosion. The additional layers help ensure that the internals are not compromised if given that the IP rating slightly fails to protect from the weather.

Conclusion

Design choices made during the development of the E1 EV Charger Board (PCB) have allowed it to become far more resilient and better suited for long-term use. Protective measures baked into the PCB of the E1 will offer better performance by minimizing the risk of damage, extending operational lifespan, and ensuring consistent charging even in challenging environmental and electrical conditions.